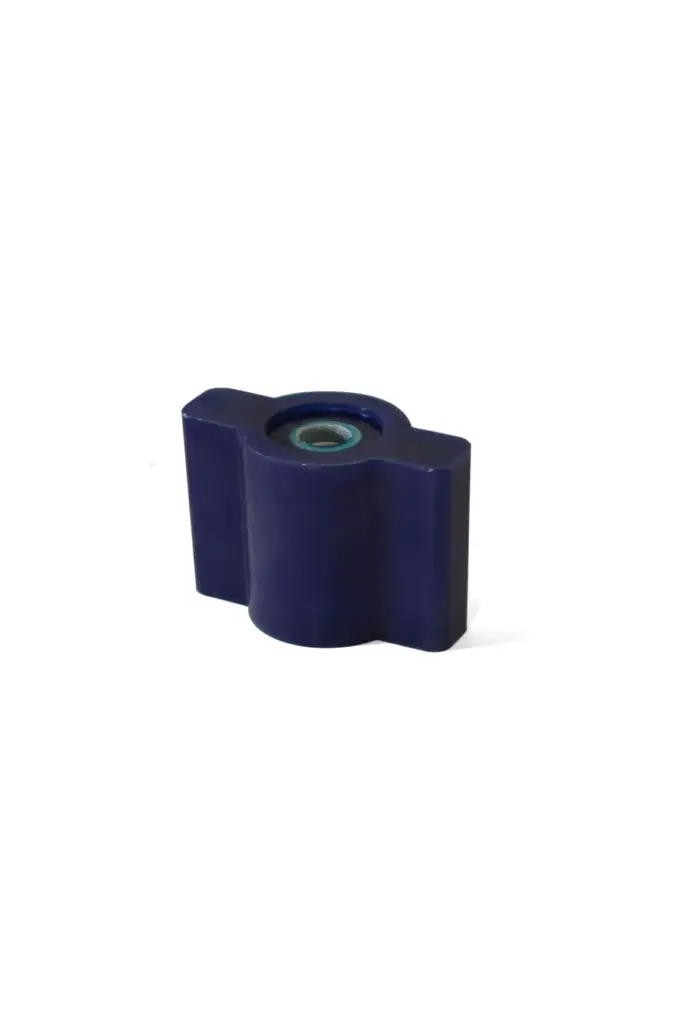

Installation tool

Accessories - Precast Concrete

Visit injection molding is a technique for manufacturing parts in large or very large series that the experts at Plasti-Tom mastered to perfection. A mold, generally made up of 2 parts (fixed and movable), is held in place in a high-pressure press and fed with plastic melts at precise temperatures depending on the viscosity of the raw material used.

We work mainly with new or recycled HDPE and LDPE plastics that match our current products, but our equipment is designed to accommodate other types of polymer.